CNC for woodworking, composite aluminium, CLT and SIP panel machining.

For woodworking, composite machining and aluminium

High-precision CNC routers that can be adapted to machine a variety of materials – wood, composite, aluminium, glass and even stone.

CNC milling - operations principles, foundations and opportunities

A CNC milling machine is a high-precision workbench that converts part drawings (CAM files) or desired parameters into precise 3D parts. The spindle of these machines moves in at least three axes – X, Y and Z – allowing the production of complex three-dimensional parts with high precision. CNC routers are widely used in a wide range of industries including joinery, manufacturing, advertising and more, offering limitless production possibilities.

Book a consultation - find out what the perfect machine is and how to integrate it into your production process

We are here to provide support and advice. Our aim is to help you find the perfect machine to meet your needs and integrate seamlessly into your workflow.

Purchasing a device from us

Gets you access to high class technologies that guarantee processing accuracy and efficiency.

Advantages of CNC milling and why buy them from us

Our milling machines are equipped with advanced features such as automated tool changing and a vacuum table, which greatly simplify the work process and reduce the time needed to produce the finished product. We offer not only the equipment, but also professional support and training, ensuring that you can make the most of your new router from day one.

High accuracy

We guarantee high precision in every step of the work, from making the contours of the parts to milling the pockets and engraving the text.

Diversity in materials

Milling cutters are capable of processing a wide range of materials - from wood and plastics to soft metals and even stone or glass.

Complex parts

The advantage of CNC milling is the ability to create complex three-dimensional parts. This option allows you to develop unique products.

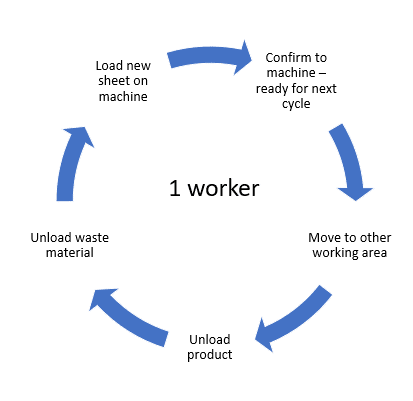

Innovation - CNC router with multiple for work surfaces

A solution never seen before in Latvia: a milling machine with multiple work surfaces. This innovative machine allows multiple parts to be processed simultaneously, minimising the need for manual part changes and waiting times. This approach not only significantly improves production speed, but also optimises the use of resources.

Find out more about integrating this technology into your company’s production process by booking a consultation.

CNC machine surface areas.

Our CNC machines are designed to work with different materials and offer a wide range of surface sizes to meet any production needs:

- 1250 × 1250 mm

- 1300 × 2600 mm

- 1600 × 3100 mm

- 2200 × 3100 mm

- 2200 × 4100 mm

- 2200 × 6100 mm

- 3200 × 13100 mm

If needed, we manufacture CNC machines with custom dimensions tailored to your specific requirements. This approach ensures maximum flexibility and efficiency in your production processes.

Thanks to precise engineering and the expertise of our team, we deliver top-quality solutions that meet even the most demanding standards.

To learn more or receive a personalized offer, contact our team today!

CNC milling machine with multiple surfaces

Innovation – CNC Milling Machine with Multiple Surfaces

With this innovative CNC milling machine, your production process becomes continuous and highly efficient. While the operator removes finished products from one surface and places new material, the milling machine continues processing on the other surface. This dynamic workflow eliminates downtime and can double productivity.

Key Benefits:

- Continuous Operation: The ability to load material on one surface while the milling machine actively works on the other.

- Increased Production Capacity: An efficient workflow significantly boosts output volume.

- Reduced Downtime: Eliminates waiting times typically caused by material loading and unloading.

- Ease of Control: The operator can easily manage the process without wasting time on manual tasks.

- Flexibility: Suitable for both large and small production volumes, optimizing workflows regardless of project specifics.

This type of CNC milling machine is the perfect solution for achieving higher efficiency and reducing production costs. With continuous operation and maximum productivity, your business can reach new heights!

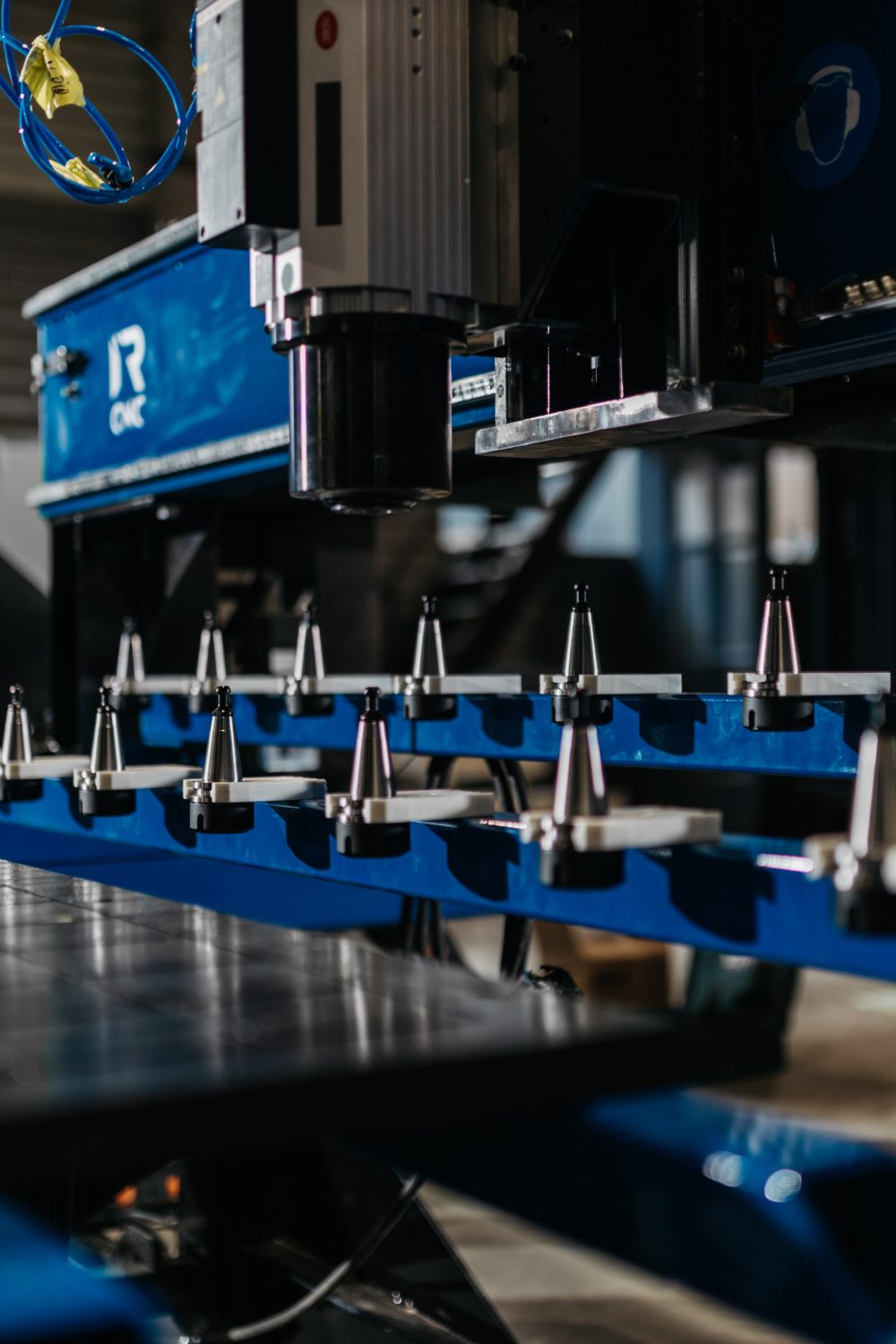

Automatic tool change – an essential upgrade for your CNC machine

Automatic Tool Change Station: Enhancing CNC Machine Efficiency

The automatic tool change station significantly improves the efficiency of CNC machines by reducing downtime and allowing operators to focus on more critical tasks. This advanced functionality offers numerous benefits that make the production process faster, more precise, and versatile.

Key Advantages:

Reduced Work Time:

Manual tool changes can take up to 15 minutes per change, while an automatic tool changer accomplishes the task in just a minute. For instance, if four tool changes are needed for a single sheet, the automatic system can save up to an hour per sheet, greatly increasing productivity.Use of Specialized Tools:

The automatic tool changer enables the use of specialized tools that are challenging to handle manually, such as 90-degree reducers or other complex tools for specific tasks. This expands the capabilities of the CNC machine, allowing for more complex processing.Minimized Human Error:

Automation eliminates the risk of errors associated with manual tool changes or incorrect installations. This ensures precision and consistent quality in every process.Relieves Operator Workload:

With automatic tool changes, operators are freed from time-consuming and repetitive tasks, allowing them to focus on other essential production activities or equipment monitoring.Efficiency Boost of up to 2x:

By reducing downtime and optimizing workflow, the automatic tool changer significantly accelerates production processes, enabling more parts to be processed in less time.

An automatic tool change station is not just an investment in efficiency but a step forward in achieving more precise, faster, and versatile production. This solution keeps your business ahead of competitors and elevates operational effectiveness to a new level.

Material clamping – the foundation of precision and safety in CNC operations

Material Clamping: The Foundation for Precision and Quality in CNC Operations

Proper material clamping is essential for precise and high-quality work with CNC machines. Incorrect or insufficient clamping can lead to processing errors and damage to both the material and the machine.

IR CNC offers a wide range of clamping solutions tailored to various needs and material types:

- Manual Clamping: Using screws or clamps, suitable for small projects or specific components.

- Pneumatic Cylinders and Pressure Rollers: Providing strong and stable fixation for larger or more complex parts.

- Vacuum Systems: Ensuring precise and rapid clamping of flat materials.

- Custom Solutions: Developed according to your project requirements.

Choosing the right clamping method not only improves processing quality but also enhances safety and efficiency. Contact our specialists to find the best solution for your production needs!

Multiple spindles

Multiple Spindles on CNC Machines – A Revolution in Production Capacity and Efficiency

Equipping a CNC machine with multiple spindles unlocks new possibilities in the production process, enhancing speed, versatility, and precision. This solution is ideal for high-volume production and complex part processing, minimizing downtime and optimizing operational cycles.

Key Benefits:

Increased Production Capacity:

With multiple spindles operating simultaneously, the machine can process multiple parts or different elements in one go. This significantly reduces overall processing time.Efficiency in High-Volume Production:

The simultaneous processing of several parts makes this solution perfect for mass production, ensuring faster and more efficient output.Enhanced Precision:

Each spindle operates with high accuracy, delivering consistent quality across all processed parts.

By choosing a CNC machine with multiple spindles, you gain a solution that accelerates production and provides your business with a competitive edge. Contact us to learn more about this solution’s capabilities and how it can be applied to your production needs!

Saw installation on a CNC milling machine – an efficient and cost-effective choice

Saw Integration in CNC Milling Machines: Enhancing Production Efficiency and Reducing Costs

Integrating a saw into a CNC milling machine offers significant benefits that streamline the production process and reduce operational costs:

Reduced Material Waste:

Precise sawing ensures clean and uniform cutting lines, minimizing material waste and processing errors. This is especially important when working with expensive or limited materials.Faster Material Processing:

A saw significantly accelerates cutting processes compared to traditional milling, particularly for long or straight cuts. This reduces production time and boosts productivity.Lower Tool Wear:

A saw is specifically designed for cutting materials that would otherwise cause excessive wear on milling tools. This extends tool lifespan, reducing maintenance and replacement costs.

These advantages make saw integration into CNC milling machines a cost-effective solution for businesses seeking to improve production efficiency and economy.

IR CNC dust collection

IR CNC Dust Collection System – A Powerful and Versatile Solution for a Clean and Safe Workspace

By choosing the IR CNC aspiration system, you gain an efficient and reliable dust and chip extraction solution equipped with advanced technology tailored to your production needs. It operates in sync with your CNC machine for optimal performance.

Key Advantages:

Automatic Operation:

The aspiration system automatically turns on and off with the CNC machine, ensuring optimal energy consumption and seamless workflow efficiency.Exceptional Power:

With an impressive extraction capacity of 6200 m³/h, the system effectively collects dust and chips even under heavy loads, maintaining a clean and safe work environment.Compatibility with Multiple Machines or Heads:

The IR CNC aspiration system is designed to connect to multiple CNC machines or heads, ensuring consistent and efficient extraction for all connected sources.Convenient Big Bag Solution:

Equipped with a spacious big bag capable of holding up to 1 m³ of chips and dust, the system minimizes the need for frequent emptying, enhancing workflow efficiency.Easy Bag Replacement:

Bag replacement is quick and straightforward – it can be done using a forklift or a pallet jack, reducing the operator’s physical effort and minimizing downtime.

The IR CNC aspiration system offers the power, convenience, and flexibility essential for modern manufacturing. This solution enables your business to maintain a clean and productive workspace while maximizing production efficiency and versatility.

CNC machine with 5 axes

5-Axis CNC Milling Machine – The Solution for Complex and High-Precision Component Processing

5-axis CNC milling machines are unparalleled when it comes to processing intricate components with high precision, diverse angles, and curved surfaces. This technology is ideally suited for industries requiring complex and high-quality part manufacturing.

When to Use a 5-Axis CNC Milling Machine?

For Complex-Shaped Components:

Perfect for producing curved, asymmetrical, or geometrically complex parts, such as those in the aerospace, automotive, and medical industries.For Precise Multisurface Processing:

Ideal for components that require processing of multiple surfaces in a single operation to achieve precise angles and curved shapes.For Large and Massive Components:

Designed for sizeable parts where reduced processing time and precision in complex areas are critical.

Advantages of Choosing a 5-Axis CNC Milling Machine:

Minimized Part Relocation:

Access to five planes of a part in a single operation reduces the need for repositioning, ensuring more accurate processing.High Precision:

The 5-axis milling machine enables the creation of complex shapes with exceptional precision, essential for industries with stringent quality requirements.Reduced Processing Time:

The speed of processing complex parts increases significantly by combining multiple operations into one cycle.Broader Opportunities for Creative and Technological Solutions:

Ability to process unique angles and shapes that are impossible with traditional 3-axis or 4-axis machines.High Efficiency and Lower Costs:

Streamlined processes reduce operator time and the need for part relocation, leading to lower long-term production costs.

5-axis CNC milling machines are indispensable for processing intricate and precise parts. They not only tackle challenging tasks but also ensure higher productivity and quality, making them an ideal choice for modern manufacturing.

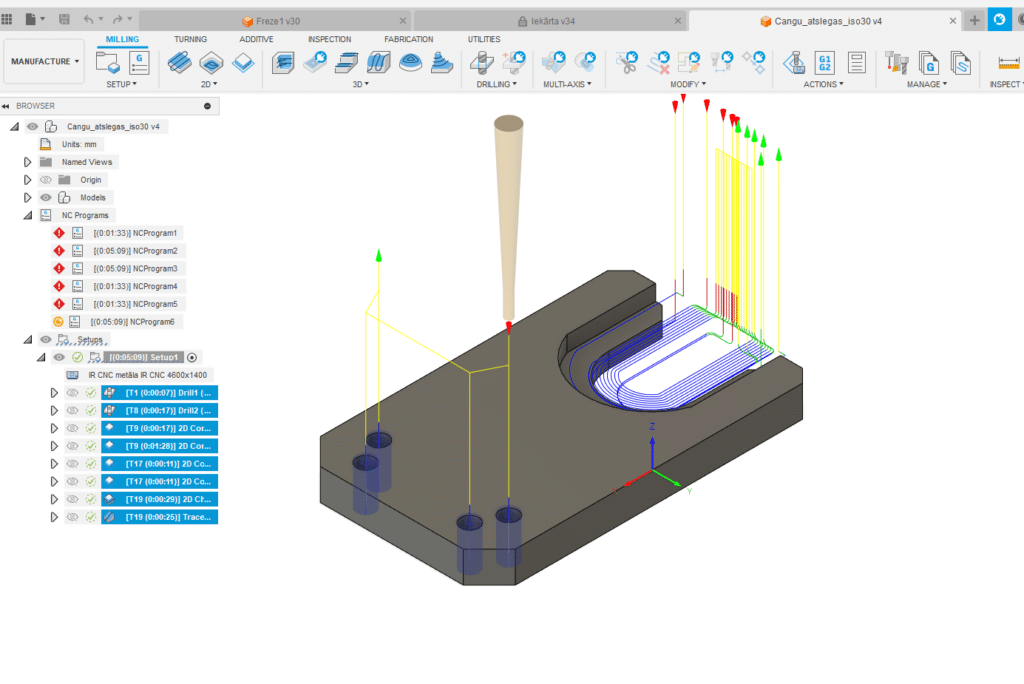

Software – a comprehensive solution for working with our CNC machines

Our CNC Machines Are Compatible with Any CAM Software, but We Recommend Autodesk Fusion 360

Our CNC machines work seamlessly with any CAM software, but we highly recommend using Autodesk Fusion 360. This software offers a comprehensive solution, covering the entire workflow from design to a ready-to-use milling file.

Key Benefits of Using Autodesk Fusion 360:

Complete Workflow in One Program:

Fusion 360 provides a full work process – from design creation, part nesting, and tool library management to generating a ready milling file for your CNC machine.Extensive Features and Functionality:

The software includes a wide range of tools tailored to your specific needs, making it suitable for both simple and complex projects.Widely Available Training Resources:

As one of the most popular CAM programs worldwide, Fusion 360 offers numerous tutorials, training videos, and forums to help you quickly develop the required skills.Support and Training from Us:

We offer training and consultations on file creation specifically for your products. Our team is available 24/7 to assist with any questions and ensure a smooth and efficient workflow.

By using Autodesk Fusion 360 in conjunction with our CNC machines, you gain a reliable and efficient solution that accelerates production processes and enhances product quality. Contact us to learn more about the software and the training programs we offer!

Explore FUSION here:

https://www.autodesk.com/products/fusion-360/overview?term=1-YEAR&tab=subscription

GH1000MC Control System – exceptional precision and functionality

Our CNC Machines Are Equipped with the GH1000MC Control System – Excellence in Precision, Reliability, and Flexibility

The GH1000MC control system provides superior precision, reliability, and adaptability, delivering top-tier manufacturing solutions for modern production environments.

Key Benefits of the GH1000MC:

Fast and Precise Control:

- Supports high-resolution positioning and accurate motion control.

- Exceptional accuracy and stability, suitable for even the most complex tasks.

Flexibility and Compatibility:

- Compatible with various drives and diverse manufacturing environments.

- Capable of managing multiple axes and adapting to specific customer requirements.

High Efficiency:

- Integrated features that minimize production stoppages and downtime.

- Fast processing and data transfer ensure a smooth production workflow.

Automation and Ease of Use:

- Built-in automatic diagnostics enable quick error identification and resolution.

- User-friendly interface with clear function layout and intuitive programming.

Robust Design and Protection:

- Integrated anti-interference technology safeguards the system from external disturbances like electromagnetic radiation.

- Compact design makes it suitable for limited spaces while maintaining high operational efficiency.

Extensive Customization Options:

- Supports the integration of specialized programs and customizations for specific equipment.

- Features multiple interfaces and advanced functions such as spindle control, servo motor integration, automatic tool change, and more.

Why Choose the GH1000MC?

The GH1000MC control system offers not only reliable and high-quality performance but also the flexibility to adapt to your company’s unique needs. It ensures maximum efficiency and precision, making it the ideal choice for modern CNC machines designed to deliver exceptional manufacturing results.

Automatic lubrication system – for durability and accuracy

All Our CNC Machines Are Equipped with an Automatic Lubrication System

Our CNC machines feature an automatic lubrication system designed to ensure reliable and continuous operation, reduce maintenance needs, and extend the lifespan of mechanical components.

Key Advantages:

Durability and Reliability:

The automatic lubrication system delivers consistent and precise lubrication to all critical components, reducing wear and minimizing the risk of mechanical damage.Reduced Maintenance Time:

By eliminating the need for manual lubrication, the system saves time and labor while ensuring the correct amount of lubricant is applied to each component.Consistent Performance:

With proper and regular lubrication, the system maintains smooth machine operation, significantly reducing unplanned downtime and boosting production efficiency.Precision and Quality:

The lubrication system minimizes friction and mechanical component temperatures, enabling more precise processing and improving product quality.Automation and Easy Control:

Fully automated and easily adjustable to meet your specific needs, the system ensures optimal results in every work cycle.

The automatic lubrication system is an integral feature of our CNC machines, designed to maintain high operational efficiency and reduce operating costs. It is crafted to ensure the longevity of your machine while delivering top-quality results on every project.

Two types of milling cutters – standard and high-efficiency solutions

We Offer Two Types of CNC Milling Machines: Standard and High-Efficiency Models

Our CNC milling machines are tailored to meet your production needs, offering both standard and high-efficiency solutions. Each option is optimized to deliver maximum performance and precision for specific applications.

Standard Milling Machines:

- Features:

- Equipped with hybrid servo motors for reliable and stable operation.

- Maximum Travel Speeds:

- X-axis: 20 m/min

- Y-axis: 15 m/min

- Z-axis: 6 m/min

- Best For:

- Ideal for standard production processes, providing high precision and reliability.

High-Efficiency Milling Machines:

- Features:

- Equipped with absolute AC servo motors and high-grade rack-and-pinion systems for exceptional speed and precision.

- Maximum Travel Speeds:

- X-axis: 50 m/min

- Y-axis: 30 m/min

- Z-axis: 15 m/min

- Best For:

- Designed to meet high-efficiency demands in large-scale production or complex projects.

Advantages of High-Efficiency Milling Machines:

- Faster Processing:

- Significantly faster part processing, reducing production time.

- High-Precision Rack-and-Pinion System:

- Ensures stable operation and excellent part quality, even at high speeds.

- Absolute AC Servo Motors:

- Provide precise positioning and efficient performance under demanding conditions.

Choose a standard milling machine for a reliable and economical solution or a high-efficiency milling machine for speed and productivity. We’ll help you select the best option for your needs, ensuring maximum efficiency and quality!

Enclosed linear guides – a solution for demanding conditions

Enclosed Linear Guides: The Ideal Solution for Challenging Environments

Enclosed linear guides are the perfect choice for applications involving concrete or dusty work environments. This design ensures longer guide lifespan and reliable CNC machine performance, even in demanding conditions.

Key Benefits:

Protection Against Contamination:

- Enclosed guides are equipped with special guards that effectively prevent dust, chips, and other particles from reaching the linear guides, protecting them from damage and wear.

Extended Lifespan:

- The added protection significantly increases the durability of linear guides, reducing maintenance frequency and costs.

Reliability in Harsh Conditions:

- This solution is particularly suited for environments with high levels of dust, such as those involving concrete or other abrasive materials.

Consistent Performance:

- Even when large amounts of dust are generated during processing, the guide guards ensure smooth and precise CNC machine operation.

Enclosed linear guides are indispensable for operations in harsh environments where dust or debris could otherwise shorten the lifespan of machine components. This solution not only provides protection but also ensures long-term efficiency and reliability for your CNC machines.

Custom additional equipment – tailored solutions for your production needs

We Offer a Wide Range of Custom Additional Equipment for Your CNC Machines

Our extensive selection of custom additional equipment enhances the versatility and efficiency of our CNC machines, ensuring they fully meet your specific requirements and production processes.

Available Custom Equipment Solutions:

Automatic Loading Lifts and Mechanisms:

- Automated material loading and unloading significantly reduce operator workload and downtime, enabling faster and more efficient production.

Specialized Milling Heads:

- We offer a variety of milling heads designed to process unique materials or perform complex tasks, such as angle milling, deep engraving, or creating non-standard shapes.

Machine Integration into Production Lines:

- Our engineering team can seamlessly integrate the CNC machine into your existing production line, ensuring smooth workflow and maximum efficiency.

Other Customizations:

- Solutions tailored to specific projects, including:

- Additional tool change stations.

- Non-standard work surfaces.

- Customized control systems or software integration.

- Solutions tailored to specific projects, including:

Why Choose Custom Equipment?

Production Flexibility:

- Enable processing of various materials and execution of a wide range of tasks.

Process Automation:

- Reduce manual labor and improve production efficiency.

Long-Term Efficiency:

- Tailored machines optimize production cycles and reduce costs.

Our specialists work closely with clients to design and implement solutions that best fit your production needs. Contact us to receive a personalized offer and equip your production with the latest technology!

Delivery, installation, training, and service – comprehensive support for starting your production

Choosing Our CNC Machines: High-Quality Technology with Comprehensive Support

By selecting our CNC machines, you receive not only top-quality technology but also comprehensive support to ensure a smooth and efficient transition to your new equipment.

Our Services:

Delivery:

- Delivery within the Baltic States is included in our offer. Your machine will be safely and promptly delivered to avoid any delays in your production process.

Installation and Calibration:

- Our professional team will handle the installation and calibration of the machine at your premises, ensuring it is ready for operation from day one.

Training:

- Free training on machine operation and Fusion 360 software to equip your staff with the skills needed for quick and efficient startup.

Warranty:

- A 2-year warranty on all our CNC machines provides peace of mind and confidence in their quality and reliability.

Fast and Efficient Service:

- Any issue will be resolved within 5 business days.

- Our warehouse is always stocked with the necessary spare parts to ensure quick and efficient repairs or maintenance.

Why Choose Us?

With our delivery, installation, training, and service offerings, you receive full support at every stage of equipment implementation. We ensure that your production process remains seamless and efficient, giving your business the best opportunity to succeed with modern technology.

Cost calculator (CNC milling)

Choose the dimensions you want, add the extras you need and browse the different configurations to find the best solution for you.